Mining Safety

Mining has a wide range of health and safety hazards that are different from those in other industries. Hazards are introduced through the mining processes, machinery and mobile equipment such as large vehicles. Risks can increase as mines in general get deeper and more expansive. If these hazards are left unchecked, the resulting hazards can cause serious injuries, death or occupational illness.

Mining Hazards

Mine safety is designed to prevent death, disease and injury in the mining industry and to promote safe workplaces for the miners. Mine safety covers a number of issues and safety of personnel and equipment in the mining industry.

Dust inhalation or coal dust is one of the most common concerns for miners. Miner’s lung is a form of the occupational lung disease group pneumoconiosis. The effects of miner’s lung can vary in severity from shortness of breath to scarring of the lung tissue. Mining companies must have a dust control plan, and companies should ensure that the dust control instrumentation is working properly. Mine workers should be trained on the hazards of over-exposure to coal mine dust. Respiratory protection should also be used when dust control protection is being installed, maintained or repaired.

Most, if not all, mines are full of noise with the constant drilling and the use of heavy machinery. This leads to the potential for hearing damage. Most workers won’t notice the damage to their hearing until long after they were first exposed to the noisy environment. Over-exposure to excessive noise can result in tinnitus, sleep disturbances, concentration problems and even permanent hearing loss. To protect workers against noise, mining companies should evaluate working conditions and noise exposure through the use of dosimeters. Companies should ensure proper use of personal hearing protection amongst noise-exposed employees, while providing necessary health and safety training.

44% Of all workers sustain a form of musculoskeletal disorders (related to excessive physical effort, bodily movement, repetitive motion)

A common health risk that miners face is heat stress. Overexposure to heat and humidity can cause the body to become fatigued and distressed. When there is a possibility of heat stress, companies should consider the work rate, working climate, worker clothing and respiratory protective equipment. Possible steps to reduce heat stress is to control the temperature, reduce work rate, and lessen the length of exposure to the hot environment. To aid in reducing heat stress, workers should be using specialised protective clothing that incorporates personal cooling systems or breathable fabrics and using specific instrumentation to monitor the health of workers at risk.

AREAS OF SAFETY

Here are typical areas of safety when discussing mine safety:

- Occupational Safety & Health

- Process & Production Safety

- Workplace Safety

- Fire & Explosion Safety

- Structural Safety

- Environmental Safety

10% Of all workers fall victim to exposure to harmful substances or environment.

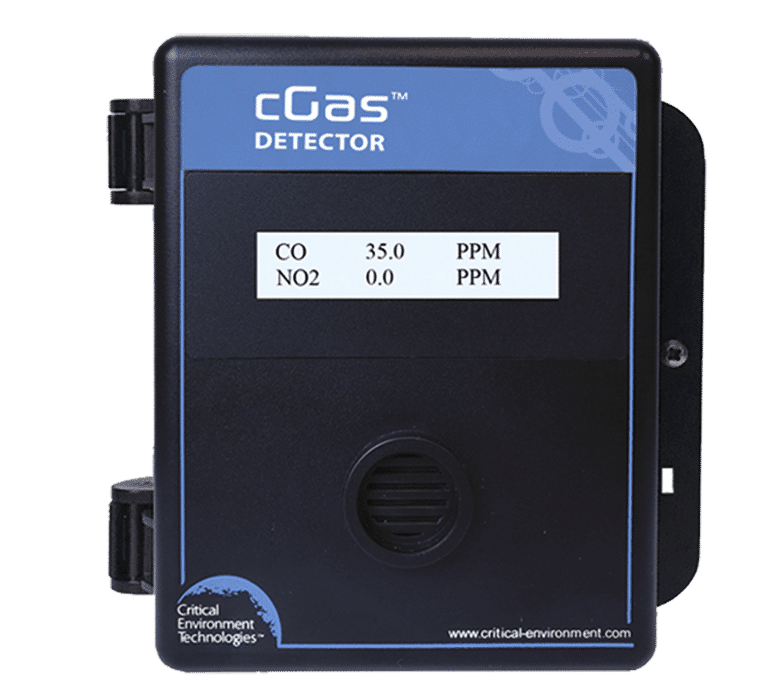

GAS DETECTION

Finding the right gas detector, and making sure it is in perfect working order, can mean the difference between life and death in environments where poisonous gases potentially exist. Confined spaces need to be tested before entry for oxygen, combustible gases and toxic gases and vapours.

TYPES OF MONITORING

There are two categories for monitoring for dangerous gases when entering and approaching a confined space area:

- Area Monitoring

- Personal Monitoring

RADON ASESSMENT

Radon is a colourless and odourless noble gas that occurs from the decay of Radium-226. Radon is considered a significant contaminant that affects air quality in underground mines and is known to form in basements of homes. Epidemiological studies show that miners exposed to elevated levels of radon have an increased risk of developing lung cancer. Companies should monitor the levels of radon to eliminate the risk of developing lung cancer through instrumentation for their workers.

Think Protection for all

Respiratory Protection

Respiratory hazards, including oxygen-deficient atmospheres and airborne contaminants like dusts, gases, and fumes, pose a real threat to workers. Protect your workers by filtering hazardous particles from the air, purifying the air, or supplying clean air from an outside source. Since respirators provide such a vital function, they’re one of the most important pieces of a worker’s safety.

TSI Portacount Fit Tester

Simplify your fit test program with one consistent and objective fit testing experience across any respirator you use. SCBA masks, Air Purifying Respirators (APRs), and N95s for medical calls can all be fit tested with the PortaCount platform.

Achieve a better respirator fit for more staff in less time. The PortaCount Fit Tester boosts your productivity by making the entire respirator training and fit testing process more efficient.

- Fast effective fit testing

- Run multiple fit testing’s in one session

- Fit checks all respiratory masks

24% of workers sustain injuries through contact with objects or equipment (including struck by rocks, crushed stone, contact with equipment, machinery).