Environmental Safety

When energy companies, or companies that use or produce substances at a site or facility, there’s always a chance those substances will spill or leak. If a spill or leak occurs, companies must manage and clean up any contamination and return the soil to a normal state.

Monitoring & Testing

Environmental remediation consists of the removal of soil and sediment, along with associated polluted contaminants within the soil. There are many government remediation standards set in most industrialized countries. Each country sets its own regulations on how the contaminants should be removed for the soil. These regulations set the guidelines for how an environmental assessment should be conducted and provides a history of what materials have been used on site. This will provide guidance on the type of sampling and analysis that must be conducted by the site manager or environmental consultant.

Soil testing neighbouring properties should also be considered due to past emissions and potential contamination. Examples of these emissions are fine particles (PM10 & PM2.5), aerosols and dust. What monitoring agencies want is the real-time data to prove that their levels are below regulations and can act when the levels exceed the limits.

REMEDIATION APPLICATIONS

There are several applications for monitoring aerosol such as PM10 and PM2.5, gases and VOC’s in the environmental remediation space. These include:

- Fence-line or perimeter monitoring at hazardous waste sites

- Perimeter monitoring of brownfields and remediation sites

- Perimeter monitoring of construction sites

- Community Watch Group Monitoring may also be interested in monitoring remediation sites

- Urban air pollution monitoring

- Watch groups

- Roadside emissions monitoring

Headspace sampling is an ideal way of introducing a sample into a photoionization detector. It avoids the introduction of involatile or high-boiling contaminants from the sample and it can often be used for the trace or ultra-trace determination of volatile organics with little or no additional sample preparation. However, there are many factors to consider when developing a headspace method, from correct sampling, optimization of headspace sampler parameters and techniques.

To ensure worker safety when using any detection device, make it a priority to perform daily bump tests before each use and schedule calibrations to the manufacturers specs. Regular service prolongs the life of equipment, as issues can often be identified and corrected before they turn into costly repairs. Scheduled equipment service programs mean fewer equipment purchases, while effectively protecting the most valuable asset, your workers.

Concept Controls helps you find the right equipment for any unexpected environmental events.

LONE WORKER

When the hazards of the task are added to working alone, risks rise exponentially. Working alone is already a hazard, but add the risk of being knocked unconscious by an atmospheric contaminant or fall and you have a recipe for a serious incident or fatality. The physical health of the worker is another factor that can ramp up the risk of working alone. Workers who suffer from medical conditions,

such as heart problems, respiratory issues, or even an allergy to bee stings, face a higher severity of risk by virtue of being alone. In an urban work setting, these workers may be four to 15 minutes from medical aid, but it could be hours before anyone even checks whether a lone worker is okay. Having a device that can react in isolation from a workers manipulation can be the difference of life and death.

Water Monitoring

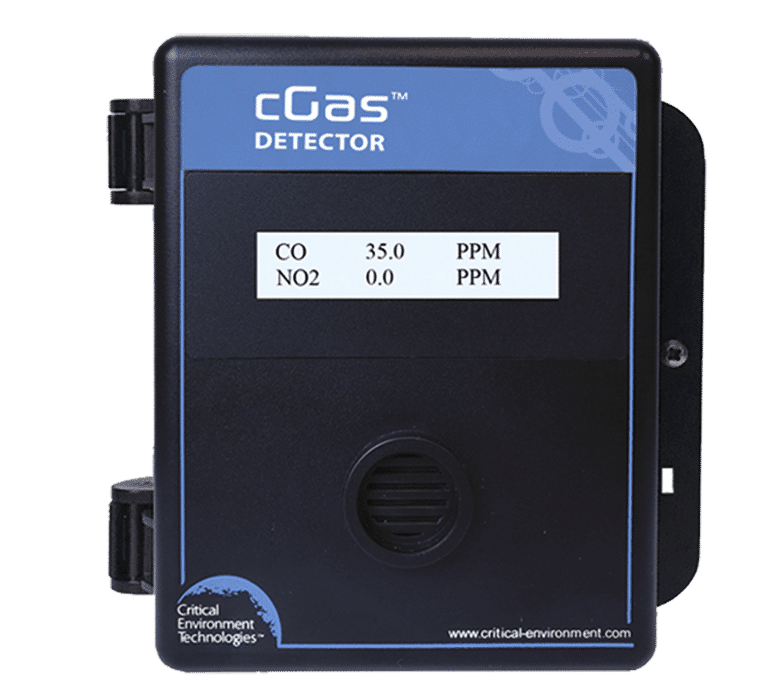

Monitoring groundwater quality and aquifer conditions can be a challenging endeavour. Being able to detect contamination before it becomes a problem can make a world of difference. The appropriate type of monitoring and the design of the system depends upon hydrology, pollution sources, and the population density and climate of the region. There are four basic types of groundwater monitoring systems:

Ambient Monitoring

Involves collection of background water quality data for specific aquifers as a way to detect and evaluate changes in water quality.

Source Monitoring

Performed in an area surrounding a specific or potential source of contamination such as a landfill or spill site.

Respiratory Protection

LEVEL OF PROTECTION

Selecting the right respirator is important. Ask yourself these questions to guide you in choosing the correct respiratory protection.

- Level of respiratory hazard?

- What are the possible contaminants?

- Are the contaminants gas, particulates or vapour?

- Duration of exposure?

Qualitative Fit Testing

Qualitative fit testing is a pass/fail test method that uses your sense of taste or smell, or your reaction to an irritant in order to detect leakage into the respirator facepiece. Qualitative fit testing does not measure the actual amount of leakage. Whether the respirator passes or fails the test is based simply on you detecting leakage of the test substance into your facepiece.

Quantitative Fit Testing

TSI Portacount

Simplify your fit test program with one consistent and objective fit testing experience across any respirator you use. SCBA masks, Air Purifying Respirators (APRs), and N95s for medical calls can all be fit tested with the PortaCount platform. Achieve a better respirator fit for more staff in less time. The PortaCount Fit Tester boosts your productivity by making the entire respirator training and fit testing process more efficient.

- Fast effective fit testing

- Run multiple fit testing’s in one session

- Fit checks all respiratory masks

Safety In Compliance

Respirator fit testing is about more than compliance with standards or about “checking the box” as quickly as possible, it’s about safety. Staff working in dangerous environments deserve the very best protection possible from a respirator. PortaCount Fit Testers deliver safety by utilizing the most effective quantitative fit testing method available to identify poor fitting masks.