Fixed Gas Detection

Comprehensive Fixed Gas Detection Services—From Sales to Calibration

With the acquisitions of Valley Technologies Ltd. and MultiGas Detection, Concept Controls has expanded its expertise in fixed gas detection systems for both commercial and industrial environments.

We offer end-to-end fixed gas detection services, including:

-

Sales and expert consultation

-

System commissioning and configuration

-

Onsite calibration and ongoing support

Our factory-certified technicians ensure your system is operating exactly as it should—including confirming the full sequence of operation. At Concept Controls, we go beyond installation—we help you create a safe, healthy, and compliant environment you can trust.

Where Our Gas Detection Expertise Makes a Difference:

- Arenas

- Automotive Dealerships

- Mechanical Rooms

- Chemical Storage

- Swimming Pools

- Oil and Gas

- Parking Garages

- Warehouses

- Hospitals

- UPS Rooms

- Airports

Our Partner Brands

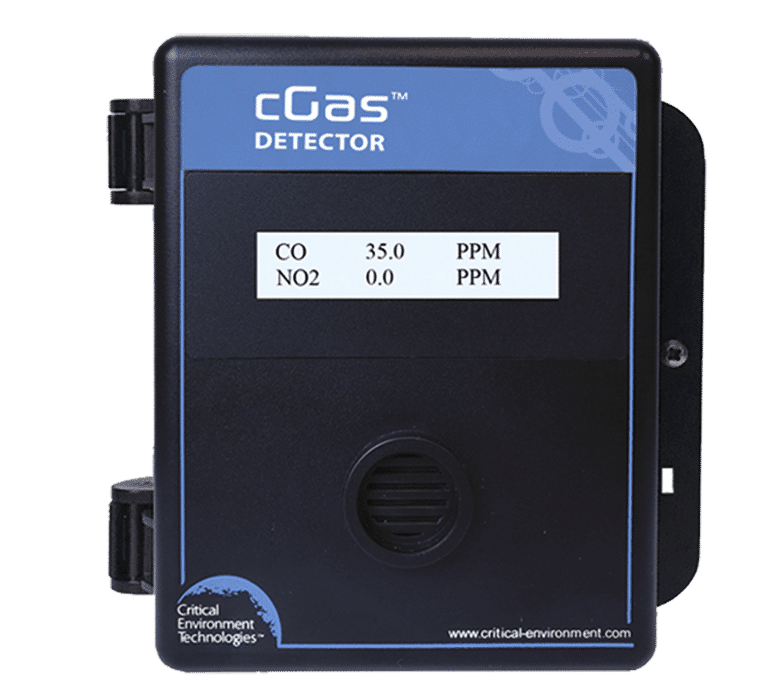

Gas Detection Consultation & System Design

Whether you are in need of parkade gas detection specifications, arena upgrades, or consultation on the most appropriate make and model of equipment, we’re here to make your job easier and steer you clear of unforeseen problems and costs.

Our experienced staff and certified electricians can provide consultation during the building design process and prior to tender, purchasing, installing or upgrading, and recommend the best products for your application.

They will ensure that the placement of the equipment is appropriate and that the installation procedure goes smoothly.

Experienced & Certified Staff

Complete Solutions

Calibration & Servicing for Fixed Gas Detection Systems

To ensure accurate performance and long-term reliability, Concept Controls recommends scheduled semi-annual calibrations for fixed gas detection systems—based on industry best practices and years of hands-on experience with building owners and facility managers.

Over time, gas sensors naturally drift in sensitivity. This can lead to:

- Overly sensitive sensors, which cause ventilation systems to run more often than necessary—driving up energy costs.

- Under-sensitive sensors, which may delay response to toxic gas levels—creating serious health and safety risks.

Our calibration process involves applying a precise test gas to each sensor and making any necessary adjustments to restore optimal sensitivity. This keeps systems running efficiently, improves indoor air quality, and helps maximize energy efficiency and sensor lifespan, delivering real savings on utilities and replacement costs.

We also consider factors like sensor age, equipment model, operating conditions, and facility when recommending a service schedule. Some environments require calibration two to four times annually, or more in harsh or high-risk applications.

At Concept Controls, your safety is our top priority. We tailor service schedules to ensure consistent, code-compliant protection for building occupants, personnel, and assets.

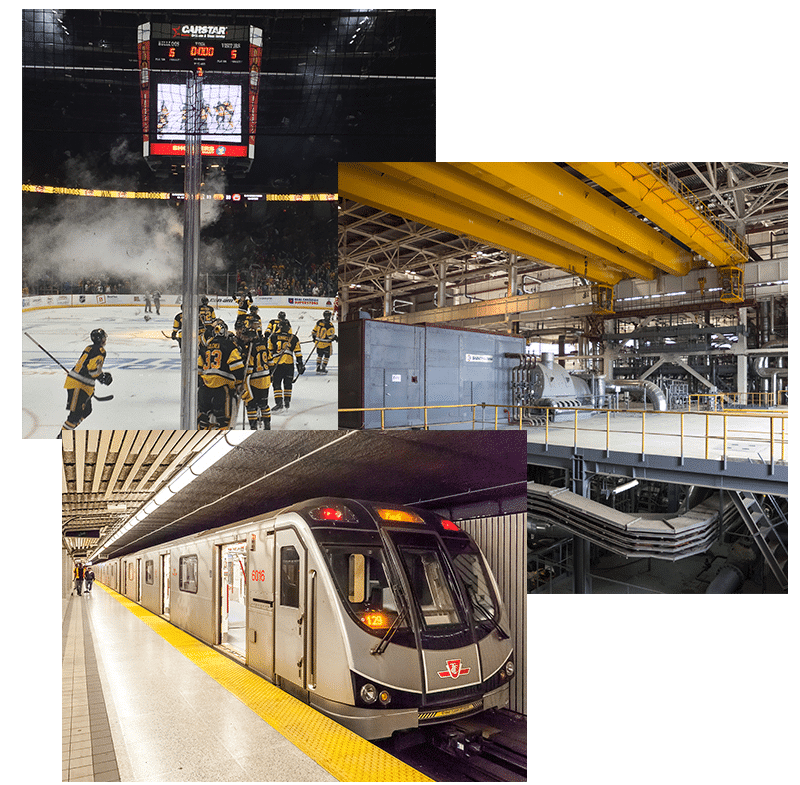

Past Projects

Parkades

Arenas

Workshop Maintenance

Fresh Air Dampers for Big Vehicles

Industrial/ Commercial Gas System Sales

Customer Testimonials

I wanted to say thank-you to yourself and the Multigas team that has put together the ASTI training sessions in Calgary. My thanks is long overdue, but heartfelt. This was the best training that I have received in my 25 years in the refrigeration trade. This training is changing the ammonia industry – it is creating a safer, more competent, more uniform and better prepared workforce.

Multigas Detection has consistently upheld its commitment to quality of services, support and timely response for all of the Devon Research Center gas detection system programming and calibrations needs; and it is a first class service we’ve come to expect.