Confined Space Safety

Refers to a space which by design has limited openings for entry and exit, unfavourable natural ventilation which could contain or produce dangerous air contaminants, and which is not intended for continuous worker occupancy. A few examples of Confined spaces are; storage tanks, compartments of ships, process vessels, pits, silos, vats, degreasers, reaction vessels, boilers, ventilation and exhaust ducts, sewers, tunnels, underground utility vaults, and pipelines.

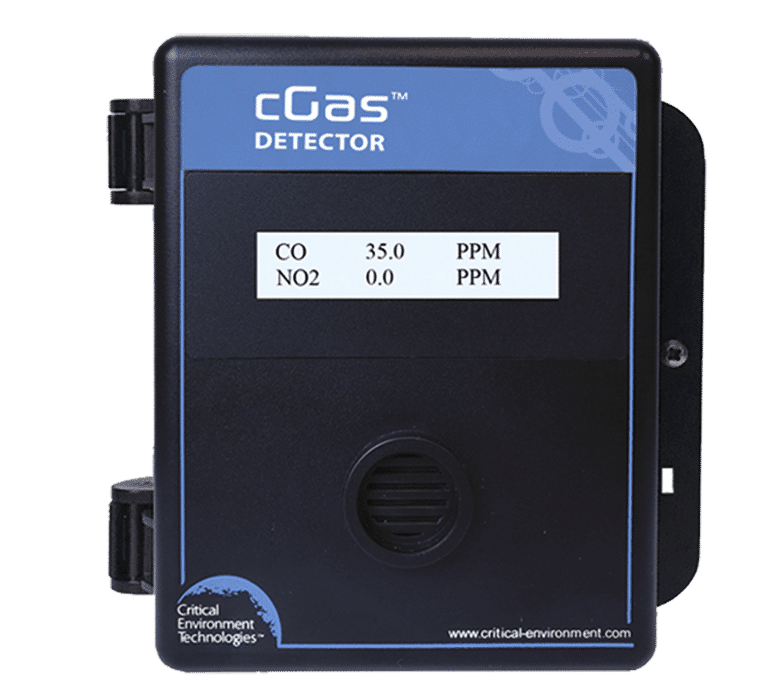

Gas Detection

Finding the right gas detector, and making sure it is in perfect working order, can mean the difference between life and death in environments where poisonous gases potentially exist. Confined space should be regularly tested to ensure atmospheric conditions remain safe. If workers exit a space and later need to re-enter, the atmosphere needs to be tested again for oxygen, combustible gases and toxic gases and vapours..

TYPES OF MONITORING

There are three categories for monitoring for dangerous gases when entering and approaching a confined space area:

- Area Monitoring

- Confined Space Monitoring

- Personal Monitoring

SAFETY IN CALIBRATION & TESTING

To ensure worker safety when using any detection device, make it a priority to perform daily bump tests before each use and schedule calibrations to the manufacturers specs. Regular service prolongs the life of equipment, as issues can often be identified and corrected before they turn into costly repairs. Scheduled equipment service programs mean fewer equipment purchases, while effectively protecting the most valuable asset, your workers.

CSA mandates testing the atmosphere in the following order: oxygen, combustible gases, toxic gases and vapors. According to CSA, approximately 1.6 million workers enter confined spaces annually.

KNOW THE REGULATIONS

Section 10 – Confined Spaces Regulation (O. Reg. 632/05)

10. (1) The employer shall ensure that a separate entry permit is issued each time work is to be performed in a confined space, before any worker enters the confined space.

(2) An entry permit shall be adequate and shall include at least the following:

- The location of the confined space.

- A description of the work to be performed.

- A description of the hazards and the corresponding control measures.

- The time period for which the entry permit applies.

- The name of the attendant described in section 15.

- A record of each worker’s entries and exits.

- A list of the equipment required for entry and rescue, and verification that the equipment is in good working order.

- Results obtained in atmospheric testing under section 18.

- If the work to be performed in the confined space includes hot work, adequate provisions for the hot work and corresponding control measures.

(3) Before each shift, a competent person shall verify that the entry permit complies with the relevant plan.

(4) The employer shall ensure that the entry permit, during the time period for which it applies, is readily available to every person who enters the confined space and to every person who performs related work with respect to the confined space.

Occupational Health and Safety Act, R.S.O. 1990, c. O.1

WORKER SAFETY

Organizations are responsible for monitoring the workplace conditions their employees are working in, identifying hazards that are or could be present, and providing their workers with appropriate protections against those hazards.

HAZARDS

When entering a confined space there are three main hazards that are presented to the worker. For a complete worker safety program ensure that these below hazards are addressed.

- Atmospheric Hazards

- Physical Hazards

- Psychological Hazards

RESCUE RESPONSE

Workers in confined spaces should be hooked up to equipment that can retrieve them if they are overcome by atmospheric conditions, medical episodes or any other possible scenario that disables the worker. You are required to have a plan in place for any confined pace entry. Ensure that you have all the requirements for your confined space entry.

- Self-Retracting Lifeline

- Tripods

- Hoists & Winches

- Harnesses

Approximately 90 deaths involving confined spaces occur every year.

Think Protection for all

Ventilation Protection

The ventilation process is comprised of the exchange of air between the inside and outside environment of a designated space, as well as internal circulation within the space. It is achieved naturally through openings or mechanically by using various types of fans. There are established standards for the required rate of ventilation in specific areas as per appropriate government authorities such as OSHA.

Respiratory Protection

Respiratory hazards, including oxygen-deficient atmospheres and airborne contaminants like dusts, gases, and fumes, pose a real threat to workers. Protect your workers by filtering hazardous particles from the air, purifying the air, or supplying clean air from an outside source. Since respirators provide such a vital function, they’re one of the most important pieces of a worker’s safety.

Apparel Protection

With so any factors to keep track of in the confined space area, keeping workers safe and providing them the right kinds of protection can seem like a daunting task. With over two decades of experience, Concept Controls has helped thousands of organizations across Canada and the United States find the best protective equipment and supplies to keep workers safe in the area of confined space.

Given the risks associated with work in confined spaces, it’s imperative that employers take training seriously. Far too many companies emphasize increasing performance and productivity to simply get the work done, failing to adequately train their workers on proper procedures, hazards, and precautions. Workers who receive sufficient training are more likely to identify and control for confined space hazards and to get the job done safely.

A review of confined space fatalities found that in each case there was a lack of recognition and testing, evaluation, monitoring, or a well-planned rescue.